Integrated Quality Assurance and Intelligent Process Routing

Implementation of Smart Camera XC-130 and V-Trace Manufacturing Intelligence By the VisionXpert Team

1. Problem Statement

In high-volume manufacturing, "defect leakage" occurs when faulty products continue through the assembly line instead of being stopped immediately. This happens because inspection systems often operate in isolation, lacking the real-time data integration needed to trigger automated stops.

As a result, companies waste time and expensive resources testing units that are already defective, driving up operational costs. Without a unified system connecting vision inspection to the wider factory, manufacturers suffer from poor traceability and cannot reliably prevent bad units from entering high-value downstream processes.

2. Solution

Our solution eliminates defect leakage by integrating ViTrox VisionXpert Smart Cameras for real-time, automated inspection. Paired with V-ONE MARS IOT Device and V-Trace Manufacturing Intelligence (Software), it ensures full traceability and automated interlocking. This unified system prevents faulty units from reaching downstream stations, reducing waste and optimizing high-volume production efficiency.

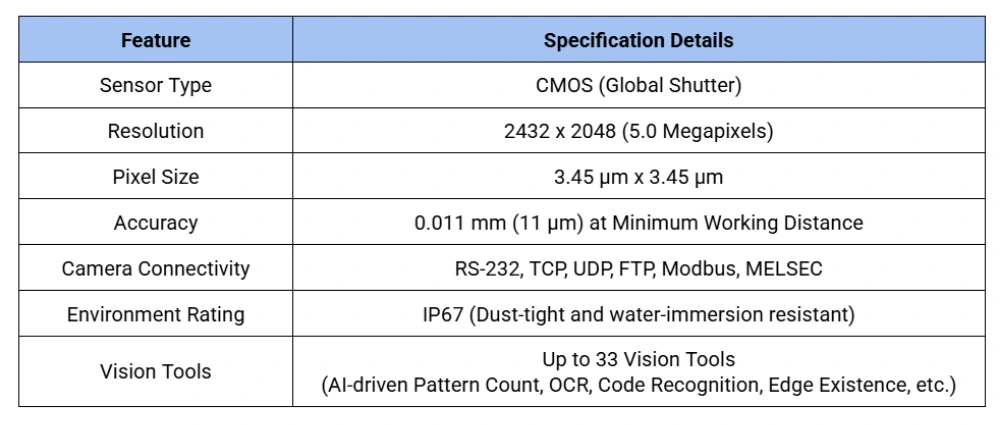

2.1 VisionXpert Smart Camera, XC-130

The VisionXpert XC-130 is a compact "mini-AOI" solution designed to complement full-scale AOI systems by providing high-resolution inspection in tight assembly cells where standard AOI machines cannot be integrated.

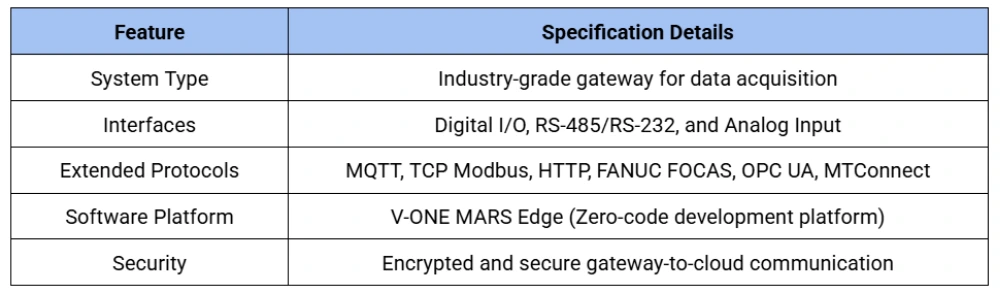

2.2 V-ONE MARS Edge Gateway

V-ONE MARS serves as the protocol bridge and automation hub, enabling seamless communication between the vision sensor and the broader factory ecosystem.

3. System Architecture and Connectivity

The system uses a tiered architecture to ensure deterministic control and enterprise-level data availability:

- Sensing/Detection Layer (XC-130 Smart Camera): Performs real-time inspection of fasteners, bolts, and barcodes using deep learning algorithms to maintain stability on reflective industrial surfaces.

- Intelligence Layer (V-ONE MARS Gateway): Acts as a "Protocol Bridge," receiving native data (TCP/IP & FTP) from the camera and translating it into the required format for the downstream test station PLCs or enterprise systems.

- Traceability Layer (V-Trace): The central repository for inspection results, high-resolution images, and reports. V-Trace manages the "digital thread," linking serial numbers to specific vision results.

4. Implementation Workflow: Automated Interlocking

4.1 Step 1: Barcode-Based Recipe Call-Up

To support high-mix production, the operator identifies the unit and selects the matching inspection template (e.g., specific bolt patterns) from the V-Trace software. This ensures the correct inspection logic is applied to the specific unit before the process begins.

4.2 Step 2: The "No Good" (NG) Signal Export

Upon completing the inspection, the camera generates a result packet:

- Method: The camera uses its native FTP client to push a result file (txt) to a dedicated directory on the V-ONE MARS’s FTP server.

- V-ONE MARS tidy up data and upload to VTrace Server.

- Data Content: The packet includes the Barcode ID, Global Pass/NG status, and ROI Mapping for each item inspected.

4.3 Step 3: Downstream Interlock (Test Station)

When a unit reaches the subsequent test station:

- The station's Smart Camera XC-130 passes a signal to V-ONE MARS to query from VTrace Server for the result file matching that unit's ID.

- If V-Trace has flagged the unit as "NG", V-ONE MARS sends a "Bypass" signal via Modbus TCP to the station.

- The test cycle is inhibited for the unit, preventing defective units from entering downstream processes, saving test time and protecting costly test fixtures.

5. Traceability and Repair Management

The integration of V-Trace ensures that every defect is actionable. The primary objective is to pinpoint specific failure locations, allowing for surgical repairs and minimal rework time.

- ROI Mapping: By utilizing Region of Interest Mapping, V-Trace enables users to identify the failure area coordinates for the repair station.

- SPC Tracking: V-Trace pairs with VONE Visualization Analytic to aggregate individual ROI Mapping data to generate Statistical Process Control (SPC) reports, helping managers identify if a specific assembly tool or robotic cell is trending toward failure.

6. Conclusion

Integrating the Smart Camera XC-130 with the V-ONE MARS Gateway and V-Trace software creates an intelligent, interlocked production environment. This solution eliminates the waste associated with unnecessary re-testing and provides the granular data required for true Industry 5.0 smart manufacturing.