High-Speed Connector Inspection with VisionXpert Smart Camera

Background

A global electronics component manufacturer aimed to enhance its final quality inspection process for a high-precision connector. The inspection required verifying that four contact pins were present and properly seated, as well as confirming the presence and correct alignment of two plates, one on each side of the connector. Previously, these checks were performed manually under magnification. While effective at low volumes, manual inspection became a bottleneck as production increased. Operators struggled to maintain consistency at higher speeds, which led to missed defects, slower throughput, and rising labour costs.

Challenges

The primary challenges included human fatigue and inconsistency during repetitive visual checks, the risk of overlooking subtle misalignments or missing components, throughput limitations with manual cycle times averaging two to three seconds per connector, and the absence of automated traceability for quality assurance and compliance purposes.

Solution

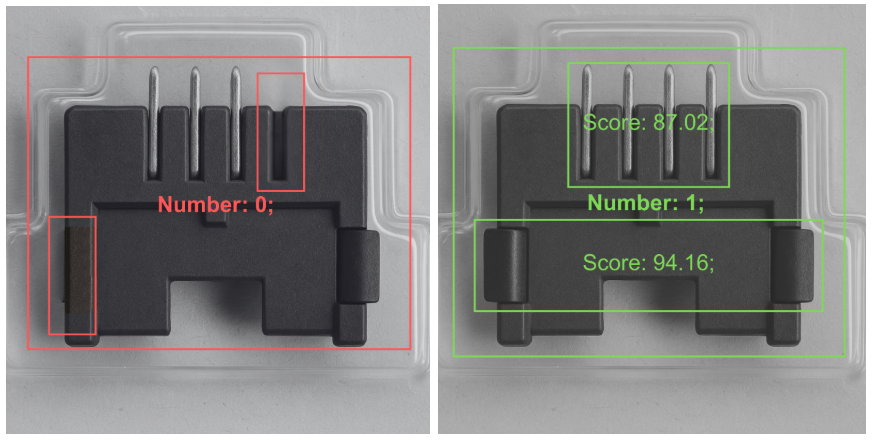

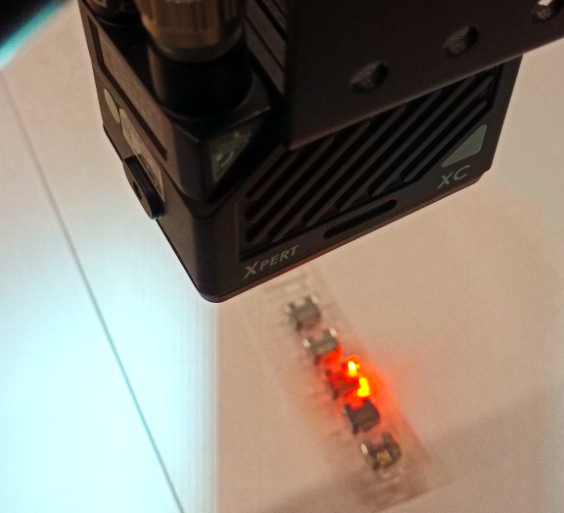

To address these issues, the manufacturer integrated the VisionXpert Smart Camera directly into the production line, replacing the manual inspection station. Configured with AI-powered vision tools, including pattern existence detection and precision counting, the system instantly confirmed the presence of all four pins and validated the position of the two plates on either side. Any missing, misaligned, or incorrectly positioned parts were flagged in real time, and each inspection result was logged with image evidence to ensure full traceability. Operating inline with the conveyor, VisionXpert enabled a continuous, hands-free inspection process that maintained accuracy while keeping pace with production demands.

Results

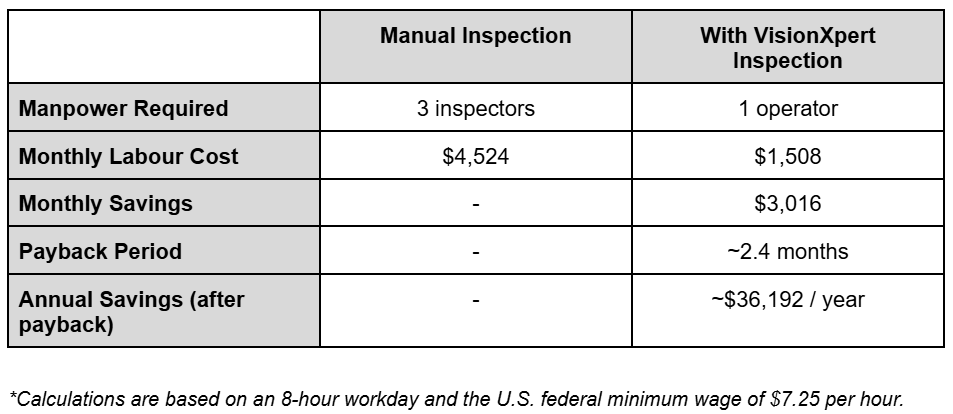

In internal testing with similar connector types, average inspection time improved from two to three seconds per unit to just 0.1 seconds, a speed increase of 20–30× compared to manual checks. This allowed significantly higher throughput without creating production bottlenecks. Defect detection remained consistent and fatigue-free across all operating hours. Such performance typically enables a return on investment in less than three months, driven by higher output, reduced rework, and fewer quality escapes. In addition, the system captured and stored every inspection, providing full traceability for audits and compliance.

Conclusion

By replacing manual inspection with VisionXpert Smart Camera, the manufacturer eliminated a critical bottleneck while ensuring 100% component verification. With its rapid inspection time, real-time defect detection, and complete traceability, VisionXpert transformed quality control from a labour-intensive task into an automated, high-speed safeguard, delivering measurable improvements in productivity and return on investment.